Top 10 Pilot Ladder Non-Compliance Mistakes

Pilot ladder non-compliance can take many different forms. Rigging a compliant and more importantly SAFE pilot ladder is effectively your vessels welcome doormat. It demonstrates you have a competent crew and that the vessel is generally well run.

However maritime pilots come across many unsafe pilot ladders. Here we’ll count down the most prevalent non-compliances pilots find when attending a vessel.

10. Damage To The Pilot Ladder

9. Painted Pilot Ladder Steps

8. Pilot Ladder Not Secured To Ships Side

7. A Pilot Ladder over 30 months without a retest

6. Pilot Ladder Spreader Braced Against Stanchions

5. Pilot Ladder Secured to Railings

4. Accommodation Ladder Not Secured To Ships Side

3. Outboard Stanchion Missing From Lower Platform

2. Shackles Over Pilot Ladder Side Ropes

1. Retrieval Line or ‘Tripping Line’

10. Damage To The Pilot Ladder

Damage can take many forms, from split steps, warped spreaders, damaged side ropes, the steps not sitting horizontally and steps/ropes contaminated with cargo residue. Whatever the reason these issues should be identified by the Pilot Ladder Pre-Use Checklist and any pilot ladder showing damage needs to be repaired as per the regulations (as a temporary measure) and/or be replaced.

9. Painted or Varnished Pilot Ladder Steps

This fairly common non-compliance may be done with the best intentions of giving the pilot ladder a longer life or to make it more visible at night, but it immediately makes the ladder non-compliant. It is important the structure of the ladder can be seen so no coatings are allowed. These coatings may also interfere with the non-slip properties of the pilot ladder. Most high quality ladder have heat treated steps to improve their longevity so no coating is actually needed.

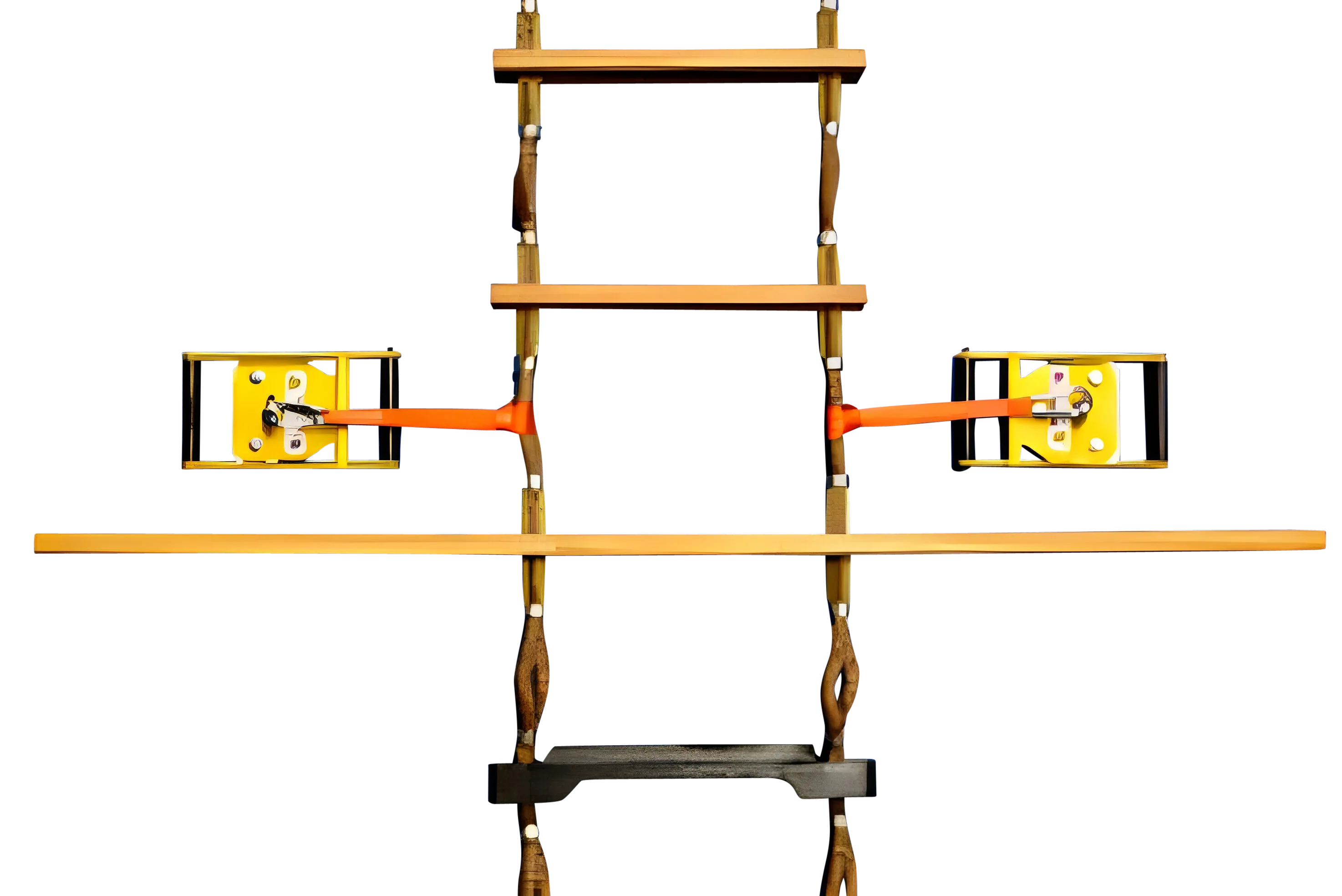

8. Pilot Ladder Not Secured To Ships Side

When a combination rig is used it is a requirement that the pilot ladder extends at least 2 metres above the lower platform and is secured to the ships side 1.5m above the platform. This prevents long pilot ladders swinging uncontrollably, makes the climb easier and the transfer from pilot ladder to accommodation ladder much safer. When securing the ladder either recessed pigeon hole lashing points or magnetic clamping devices (https://www.fathomsafety.com/articles/pilot-ladder-magnets-requirements) can be used. The important thing is that both sides of the ladder are secured independently to prevent two much weight being applied to the lashing, or where used, to the magnetic clamping devices.

7. A Pilot Ladder over 30 months without a retest

This is a still a common issue. When a ladder reaches 30 months of age the pilot ladder should have a load test performed by the manufacturer or an approved testing station. This then certifies the ladder as fit for use for a further 30 months. Generally speaking if a ladder has been in use for 30 months it will actually need replacing so this is often the best option. Spare pilot ladders however, that have been stored carefully and not used, may be good candidates for retesting

Remember when the ladder turns 30 we must check that it’s sturdy.

6. A Pilot Ladder Spreader Braced Against Stanchions

It may be an instant way to secure a pilot ladder but bracing a pilot ladder spreader against the stanchions is highly dangerous. Spreaders are simply not designed to operate like this and are likely to weaken and fail with this malpractice.

Pilot ladders need to be secured to the deck, either by shackling the thimbles to the deck strong points if the ladder is used at it’s full extent or by using two ropes, each having a breaking strain not less than 48kN, and secured to the ladders side ropes by means of a rolling hitch such that the weight is borne by the ropes and not by the steps, wedges or securings.

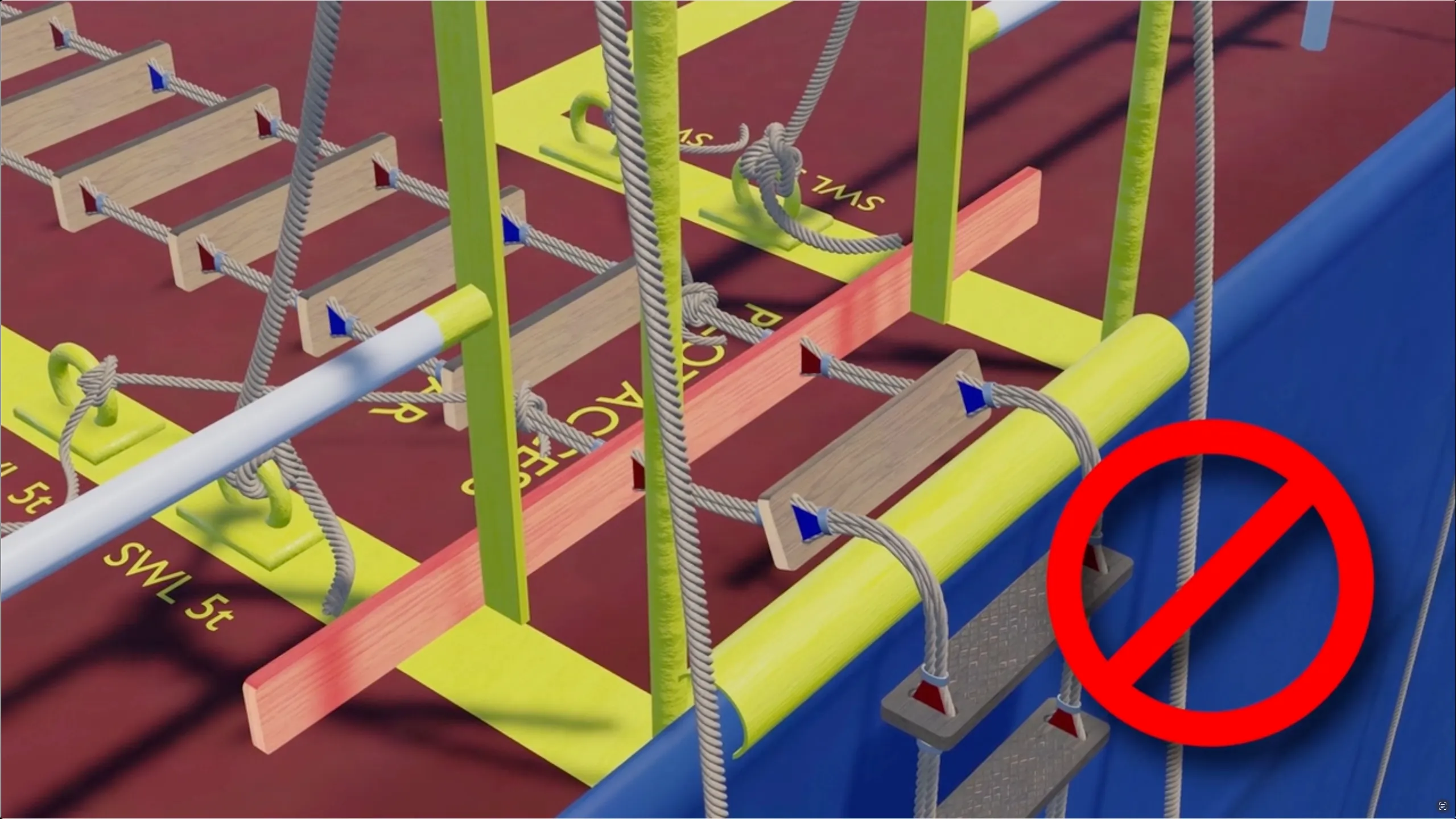

5. Pilot Ladder Secured to Railings

It always a sobering moment when as a pilot you climb to the top of the ladder to find it was secured to the vessels railings. The ladder must be secured to the certified deck strong points. If they don’t exist the ship needs to be fitted with them and have them tested to 5t SWL. Railings are simply not designed for this purpose and could easily fail.

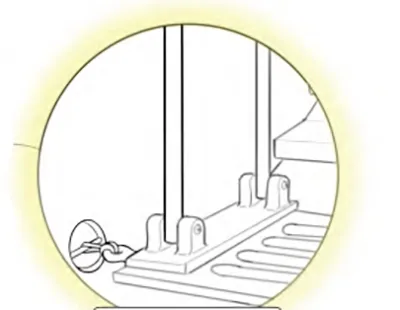

4. Accommodation Ladder Not Secured To Ships Side

Just as the pilot ladder must be secured to the ships side to stop is swinging like a huge pendulum the same goes for the accommodation ladder. This can be done either by use of a recessed pigeon hole lashing point or by means of a pneumatic suction pad. Magnets are not suitable for this purpose as they are generally not strong enough to prevent the weight of a accommodation ladder from swinging as the vessel rolls.

3. Outboard Stanchion Missing From Lower Platform

It may seem like a minor point but the outboard stanchion offers the pilot an extra degree of protection and an additional handhold when transitioning from the pilot ladder to the accommodation ladder. It is essential this stanchion isn’t forgotten about!

2. Shackles Over Pilot Ladder Side Ropes

Number two on our list of biggest pilot ladder ubiquitous ‘shackles over side ropes’ method of securing a pilot ladder. This should never be done for a very simple reason – as soon as weight comes on the pilot ladder the side ropes slide through the shackles until the wedges become trapped and instantly the weight is transferred to these components.

The wedges are there to keep the ladder steps firmly in place and level they are generally made from plastic and are damaged easily. They are therefore not load bearing and can easily fail when this method is used to secure the pilot ladder.

As mentioned before the ladder, when used at an intermediate length should be secured with ropes by means of a rolling hitch such that the ropes take the weight.

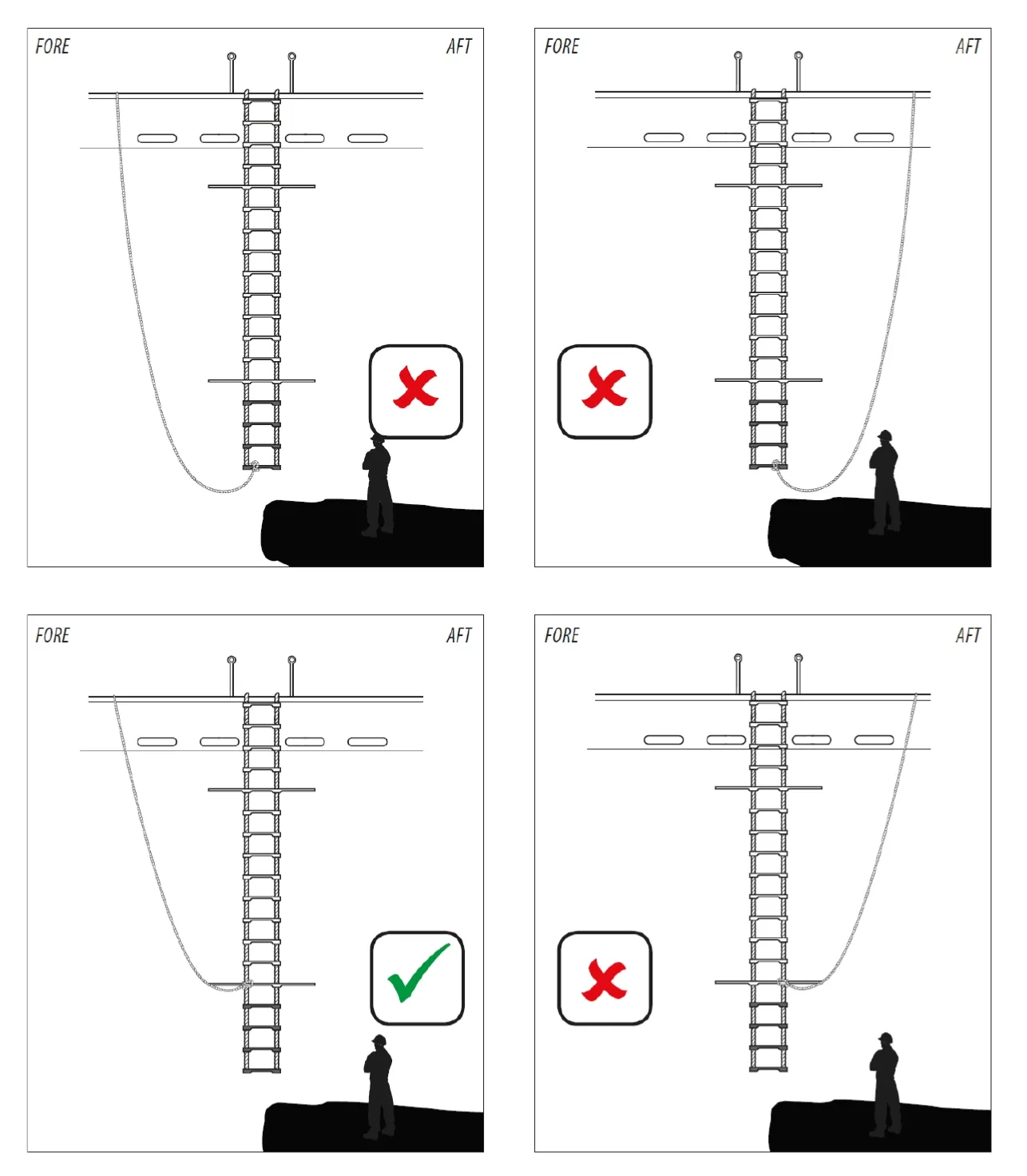

1. Retrieval Line or ‘Tripping Line’

And our number 1 mistake when rigging a pilot ladder is the pilot ladder retrieval line or tripping line (https://www.fathomsafety.com/articles/pilot-ladder-retrieval-lines-or-tripping-lines). When long pilot ladders are deployed by hand and not a winch they can be difficult to recover therefore it is understandable the crew want to use a retrieval line. Whenever a tripping line is used it must be secured at or above the lowermost spreader and lead forward.

By doing this it cannot get tangled up on the pilot boat or cause a tripping hazard for the pilot.

Remember lower most spreader going forward!

So there you have it our top ten rundown of common pilot ladder mistakes. This will account for 95% of errors found on vessels and are easy to prevent or resolve. Remember your pilot ladder is like your front door mat, it should welcome guests not worry them or worse still injure them!

With the Fathom Safety Pilot Ladder Management Service these concerns can be a thing of the past. Our headache free pilot ladder management looks after the provision, inspection, retesting and replacement of a fleets pilot ladders whilst also providing comprehensive pilot ladder training. Our bespoke sotware gives ship managers and techinical supintendents absolute visibility of their vessel's ladders, crew training competence and ladde requirements whilst Fathom Manage all of this with our partners at PTR Holland. So save yourself the headach and drop us a line at [email protected]