How To Secure A Pilot Ladder

Securing a Pilot ladder in a safe, compliant and seamanlike fashion not only ensures the safety of your pilot but also prevents unnecessary and potentially costly delays.

First of all let’s consider what we use to secure a pilot ladder. It’s important that whatever we use is dedicated solely for the purpose of securing the pilot ladder and not simply a random piece of rope from the deck locker.

There are three key areas where securing ropes are used

- For securing the ladder to the deck

- For securing the ladder to the side of the ship 1.5m above the platform when a combination rig is used

- For securing the accommodation ladder to the ships side.

Ropes Used For Securing The Pilot Ladder To The Deck

The regulations require that whatever rope you are using it is of equal strength to the side ropes. The side ropes of a pilot ladder have a breaking strain of 24kN and since there are 2 of them on each side of the ladder gives a combined breaking strain of 48kN. Therefore we need a securing rope with a breaking strain of ≥48kN. Ideally we’d use Manila rope but to achieve that breaking strain it would need to have a diameter of 25mm since no such rope is commonly produced we’d need to select the next diameter available which is 28mm. Such a rope would be impractical to use as a securing rope so this rules out Manila as an option.

There are many suitable options such as 20mm polypropylene, 16mm Polydac or 18mm nylon rope. Whatever option you choose it’s essential the ropes each have a tag stating

- Date the rope entered service

- Rope Type

- Breaking Strength

We strongly advise that wherever possible securing ropes are purchased with a ladder and disposed of when the ladder is replaced (or sooner if required). PTR Holland are able to provide pre-tagged 20mm Polypropylene securing ropes when you buy a ladder from them. This is the best way of ensuring you have a rope that is up to the job.

When securing the ladder (or rope tails) to the deck research (IMPA Study here) has found a rolling hitch to be the most effective method to achieve this.

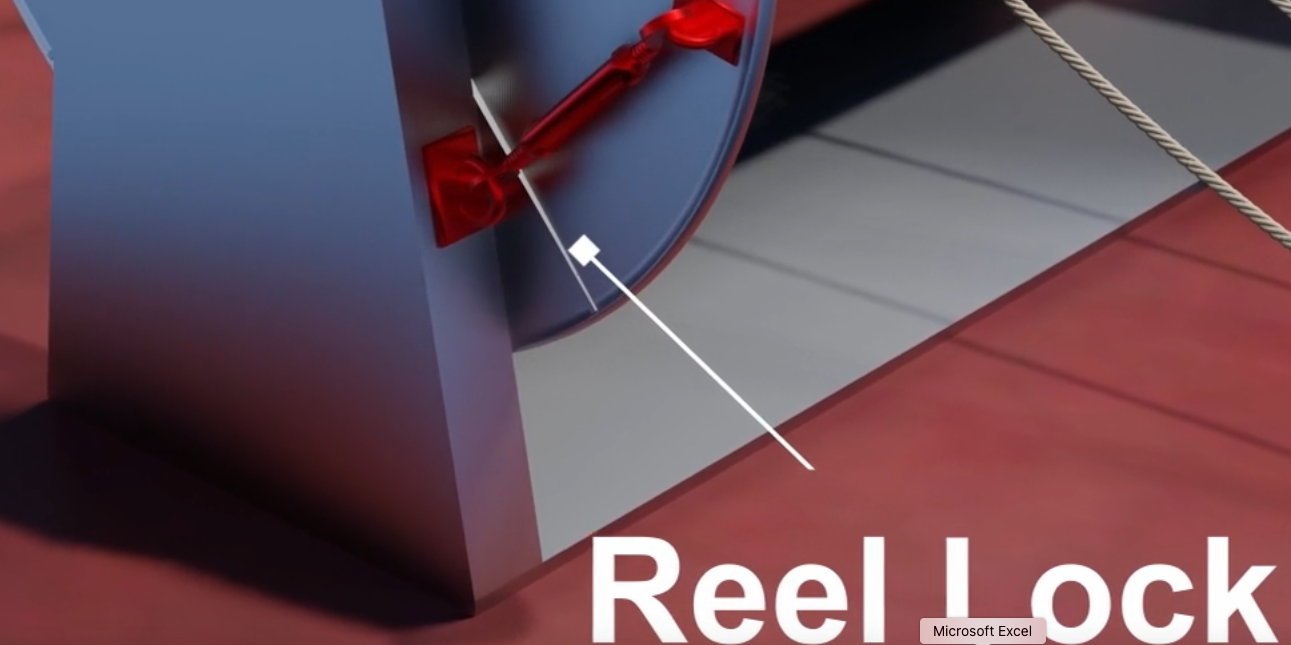

It’s also important that if the ladder is on a reel as well as securing the ladder/rope tails to the deck the winch also needs securing with either a dedicated locking pin or bottlescrew (turnbuckle). The controls should also be secured or disconnected to prevent accidental operation.

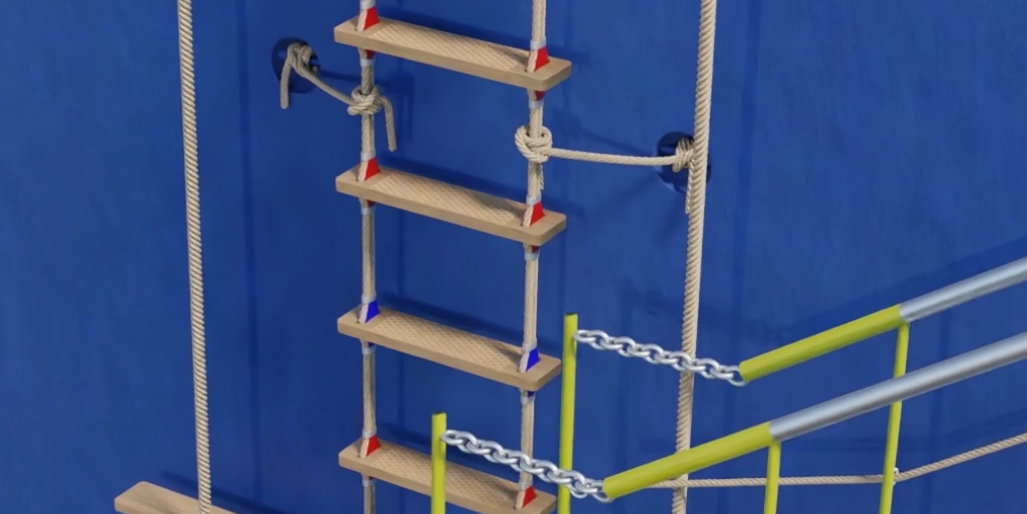

Ropes For Securing The Pilot Ladder To The Ships Side

These securing ropes are only intended to bowse the pilot ladder to the ship side to prevent it from moving off the ship’s side in a seaway and make the transfer from pilot ladder to accommodation ladder safer.

The ropes used to secure the pilot ladder side ropes to the ship’s hull shall have a holding force

of not less than 3 kN each. This small force means we could safely use 6mm diameter Polypropylene, Polydac or Nylon Rope.

Again these ropes should be tagged and only ever used for this purpose.

Ropes For Securing The Accommodation Ladder To The Ships Side

The rope used to secure the accommodation ladder to the ships side needs to be slightly stronger at 4kN. This is due to the weight of the accommodation ladder and the potential load that may be borne by the securing rope as the vessel rolls and the accommodation ladder’s momentum tries to pull away from the vessels hull.

However this is still well within the capability of 6mm polypropylene, Polydac or nylon rope. Again the rope should be tagged and used purely for this purpose.

So there we have it all we needed to know about pilot ladder securing arrangements.

If pilot ladders are making your life tough why not consider the option of the Fathom Safety End-to-End service. Our pilot ladder management package can save you money on your pilot ladders, guaruntee a premium quality ISO 799 PTR Holland ladder and improve your sustainability